Can Solenoid Valve Technology Improve Water Conservation in Agriculture?

Solenoid valve technology can indeed contribute to water conservation in agriculture. Here's how:

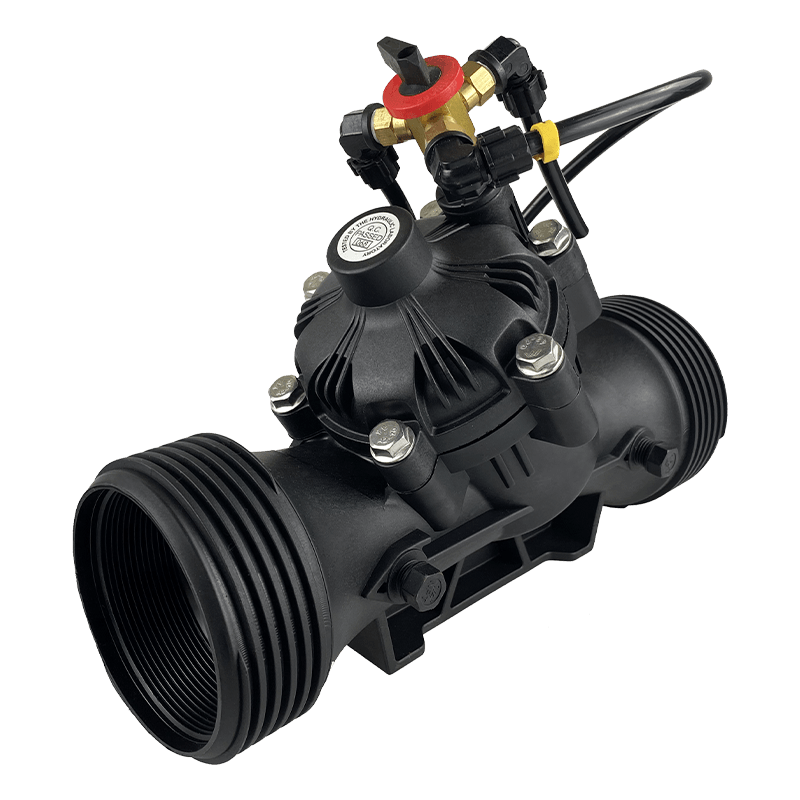

Precision Irrigation: Solenoid valves are crucial components in modern irrigation systems. They enable precise control over the flow of water to individual sections or zones. By using solenoid valves, farmers can implement precision irrigation, delivering the right amount of water directly to the crops that need it, thereby minimizing water wastage.

Automated Systems:

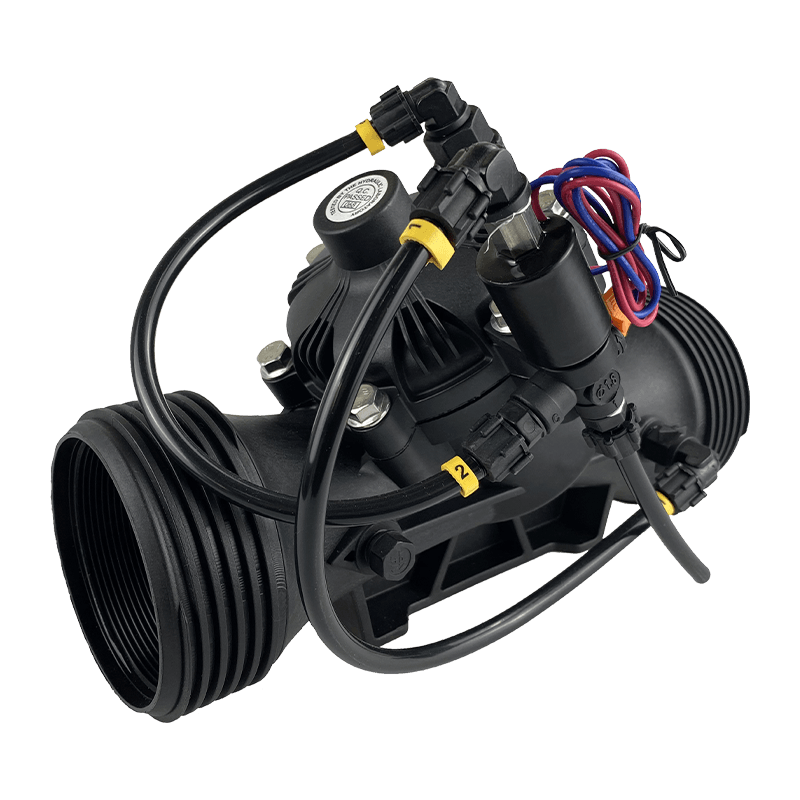

Solenoid valves are often integrated into automated irrigation systems. These systems can be programmed based on factors such as soil moisture levels, weather conditions, and crop requirements. By automating the irrigation process, farmers can ensure that water is applied only when and where it is needed, preventing over-irrigation and conserving water resources.

Zoning and Timing: Solenoid valves allow for the creation of irrigation zones. This zoning capability enables farmers to tailor water delivery to specific areas of the field, taking into account variations in soil types and crop water needs. Additionally, timing control provided by solenoid valves ensures that water is distributed during optimal periods, avoiding unnecessary irrigation during times of high evaporation.

Remote Monitoring and Control: Advanced solenoid valve systems can be equipped with remote monitoring and control features. This allows farmers to manage their irrigation systems from a distance, making real-time adjustments based on changing conditions. By remotely monitoring the system, farmers can respond promptly to issues such as leaks or malfunctions, reducing water losses.

Water Pressure Regulation: Solenoid valves can be used to control water pressure in the irrigation system. By maintaining optimal pressure levels, farmers can ensure that water is delivered efficiently to the crops. Proper pressure regulation prevents water misting, overspray, and other issues that can lead to water wastage.

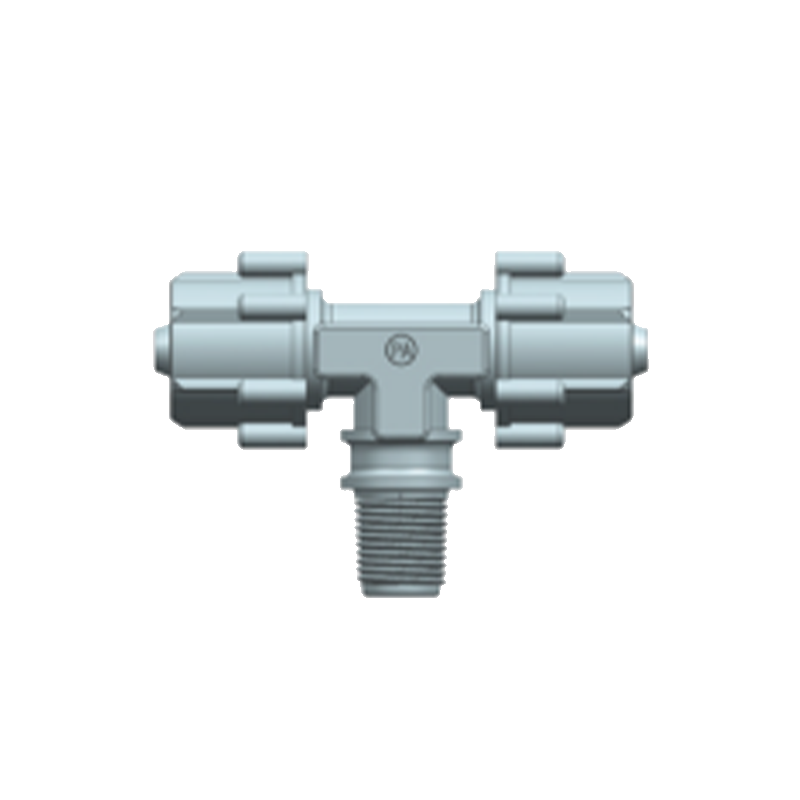

Drip Irrigation Integration: Solenoid valves are commonly used in drip irrigation systems. Drip irrigation delivers water directly to the root zone of plants, minimizing surface runoff and evaporation. Solenoid valves in drip systems play a crucial role in regulating the flow of water to individual emitters or drip lines.

In summary, the integration of solenoid valve technology in agricultural irrigation systems contributes significantly to water conservation efforts. By providing precision control, automation, and efficient water distribution, solenoid valves help farmers optimize their water usage, reduce wastage, and promote sustainable agriculture practices.

How Do Anti-Corrosive Solenoid Valves Address Challenges in Harsh Environments?

Anti-corrosive

solenoid valves are designed to address challenges posed by corrosive environments, ensuring reliable and long-lasting operation in harsh conditions. Here's how these valves address such challenges:

Material Selection:Anti-corrosive solenoid valves are constructed using materials that exhibit high resistance to corrosion. Common materials include stainless steel, plastic, and other corrosion-resistant alloys. These materials prevent degradation caused by exposure to corrosive substances in the environment.

Chemical Resistance:Harsh environments often involve exposure to chemicals that can corrode standard materials. Anti-corrosive solenoid valves are engineered to resist the corrosive effects of chemicals, acids, and other aggressive substances commonly found in industrial and chemical processing applications.

Sealing Mechanisms:Corrosion can compromise the sealing mechanisms of standard valves, leading to leaks and malfunctions. Anti-corrosive solenoid valves feature robust sealing materials and designs that maintain their integrity in corrosive environments, ensuring a tight seal and preventing fluid leakage.

Coatings and Treatments:Some anti-corrosive solenoid valves may incorporate special coatings or treatments on the valve components. These coatings provide an additional layer of protection against corrosion, enhancing the overall durability and resistance of the valve in harsh conditions.

IP Ratings for Enclosures:In environments where dust, moisture, or other contaminants are prevalent, anti-corrosive solenoid valves often come with high Ingress Protection (IP) ratings for their enclosures. This protects the internal components from environmental factors, maintaining the valve's functionality over an extended period.

Temperature Resistance:Harsh environments can experience extreme temperatures, which may affect the performance of standard

solenoid valves. Anti-corrosive valves are designed to withstand a broad range of temperatures, ensuring reliable operation in environments where temperature fluctuations are common.

Resistance to Saltwater Environments:In marine or coastal applications, saltwater can accelerate corrosion. Anti-corrosive solenoid valves are well-suited for such environments, as they are specifically designed to resist the corrosive effects of saltwater and maintain optimal performance over time.

Regular Maintenance and Inspection:While anti-corrosive solenoid valves are designed for durability, regular maintenance and inspection are essential to ensure continued effectiveness. Periodic checks can identify any signs of corrosion or wear, allowing for timely replacement or maintenance to prevent potential issues.

By addressing these factors, anti-corrosive solenoid valves provide a reliable solution for applications in harsh environments where corrosion poses a significant challenge. Their robust construction and resistance to corrosive agents contribute to extended valve life and reduced maintenance requirements.

cn

cn English

English